Steel Information

Steel is a critical component of any knife. The purpose of this guide is to provide a more detailed look into steel to help assist you in better defining what your own preferences are and why. As a word of caution this information is not intended to be all-inclusive nor could it ever be as the world of steel is ever evolving. The quest for higher performance steels has led to the development of many new, excellent materials over the years and there are currently over 3,000 different types of steel, each having its own positive and negative attributes.Of course steel is not the only factor that determines a knife’s performance. Blade geometry, heat treatment processes, handle geometry and other materials used in the production of the knife all contribute to how the end product will handle particular jobs. It is not possible to tell just by looking at a blade how well the item has been heat treated and it is only possible to make an educated guess as to how well the handle and blade geometry will work. However, by knowing the grade of steel used you are better able to understand the alloying elements involved giving you something measurable to go by when determining your own preferences.

The result of knowing the grade of steel can unfortunately put the end user into a trap of placing too much of an emphasis on the steel itself. A knife is more than just the steel that goes into it and it’s important to recognize this. In fact, so many modern steels perform so well that knife decisions can often be made based on other factors than just the marginal increases in steel performances.

Often the question of “what’s the best steel” or “which steels rank better than others in terms of best to worst” come up. There is never a truly correct and accurate response to this as the blade geometry of the product, the quality of the heat treatment, the materials used and the tasks, or goals, of the end user all will factor in to determine how well a product will perform and in turn how well the user will be satisfied with the product.

We use specific blade steels to create the most efficient balance of properties based on the anticipated applications of our products.

Steel is an alloy of iron, other metals and carbon. Stainless steel refers to a family of corrosion-resistant alloy steels which contain a minimum of 10.5% chromium. A common misconception is that stainless steels will not stain, rust, or corrode. Stainless steels will simply stain less than other steels that do not contain chromium. Each alloy in the various steels lends unique properties to the stainless steel.

When selecting the steel for the various products we factor in the overall performance requirements of what the tool will be used for, the goal price range for the end product and the costs of manufacturing and finishing the item(s). As with any materials there are generally trade-offs. For instance, while higher alloy levels and final hardness levels keep an edge longer they also will make it more difficult to field sharpen a blade. Some alloys can be found to be low in nickel, which will result in increased staining if not kept regularly oiled and cleaned after use. Knives that will be placed to hard use must be constructed with very tough steel materials so we will use steels that are considered to have high ductility (or toughness) over a higher hardened steel. Please note that final hardness levels are achieved not only by factors of composition but from proper heat treating and quenching, of which we pay great attention.

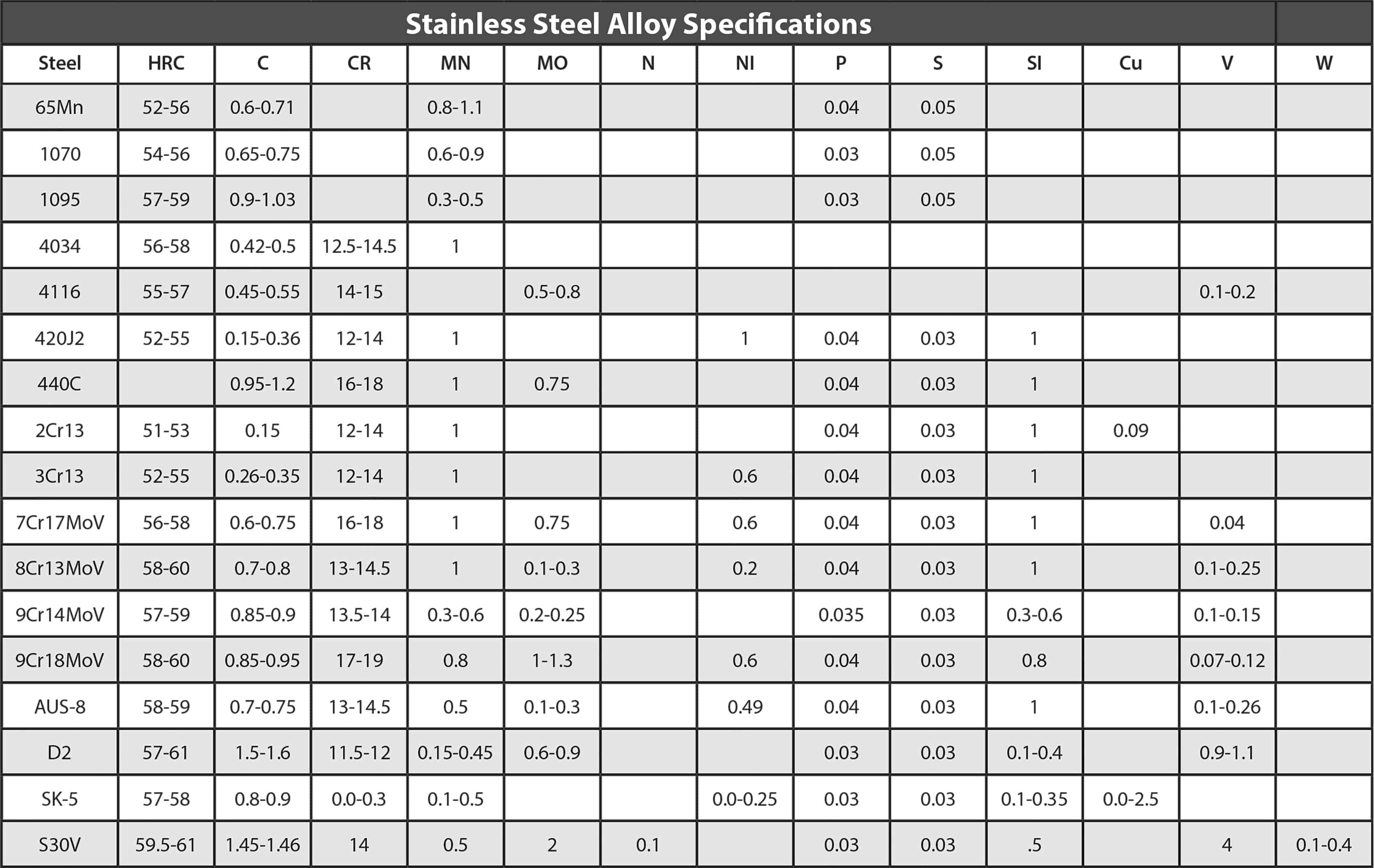

We source premium steel from many international suppliers. The information chart referenced below shows a reasonable range of the compositions of the various steels we utilize. The blade steel we use for each product is included in the catalog to help make this information easy for you to locate.

STEEL TERMS

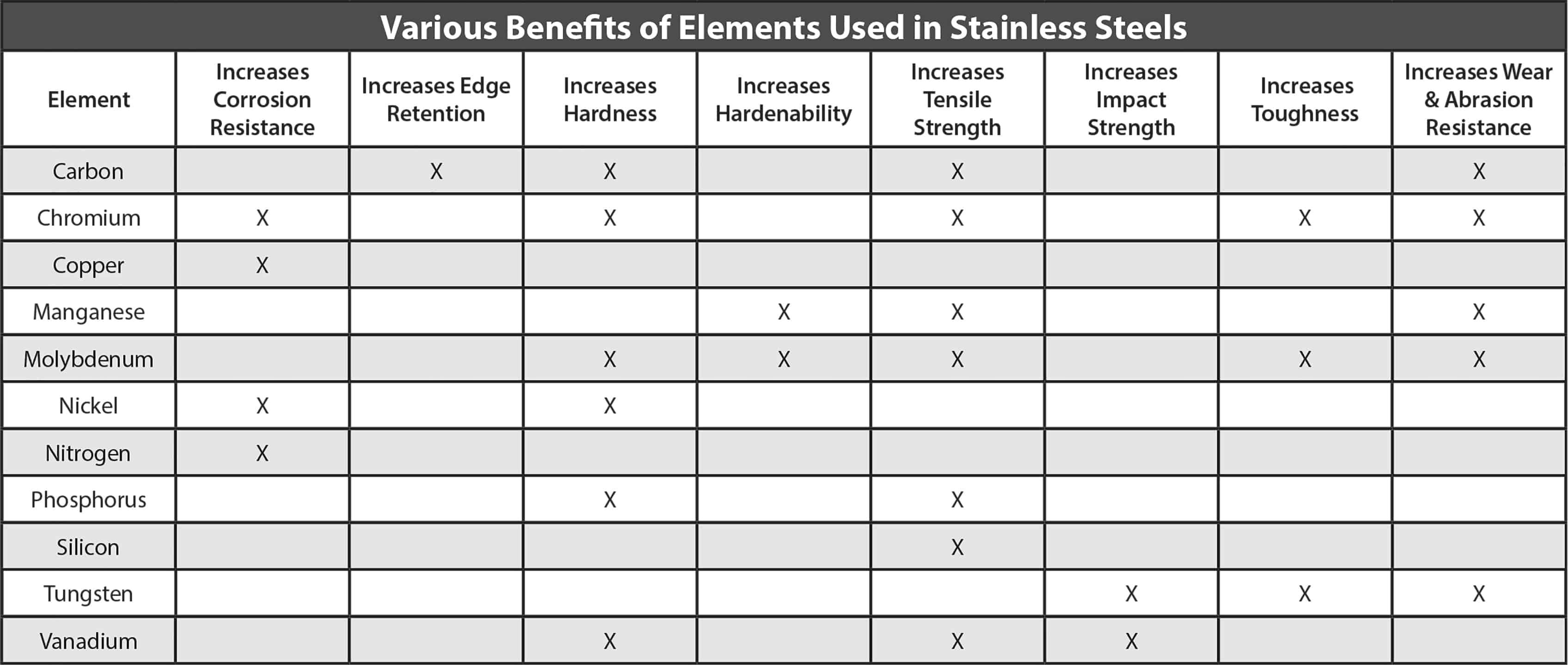

Alloy: A material that is dissolved in another metal in a solid solution. A material that results when two or more elements combine in a solid solution.Corrosion Resistant: The ability of a material to resist deterioration as a result of a reaction to its environment. Provided by the elements Chromium (Cr), Copper (Cu), Molybdenum (Mo) and Nitrogen (N).

Ductility: The ability of a material to be stretched or drawn, plastically deform appreciably before fracturing. Provided by the element Manganese (Mn).

Edge Retention: The ability of a material to resist abrasion and wear. Provided by the elements Carbon (C), Chromium (Cr), Manganese (Mn), Nitrogen (N) and Vanadium (V).

Hardness: The resistance of a steel to deformation or penetration analogous to strength. Provided by the elements Carbon (C), Chromium (Cr), Cobalt (Co), Molybdenum (Mo), Nitrogen (N) and Phosphorus (P).

Hardenability: The ability of a steel to be hardened by a heat treating process. Provided by the elements Manganese (Mn), Molybdenum (Mo) and Tungsten (W).

Heat Treating: A controlled heating and cooling process to prescribed temperatures and set limits for the purpose of changing the physical properties and behavior of the metal.

Impact Strength: The ability of a material to resist cracking due to a sudden force.

Rockwell Test (HRC): A measurement of steel hardness based on the depth of penetration of a small diamond cone pressed into the steel under a constant load.

Tensile Strength: Indicated by the force at which a material breaks due to stretching. Provided by the elements Chromium (Cr) and Manganese (Mn).

Toughness: The ability of a material to resist shock or impact. Provided by the element Chromium (Cr).

1070: This is a plain carbon steel which means it has a low resistance to corrosion and low to medium edge retention. The benefit of this steel is that it is very easy to sharpen and will take an extremely sharp edge.

1095: This is a plain carbon steel which means it has a low resistance to corrosion and low to medium edge retention. The benefit of this steel is that it is very easy to sharpen and will take an extremely sharp edge.

4034: A good quality grade of stainless steel. This steel is known for its ability to be honed to a razor sharp edge. While this steel has medium edge retention it is a very easy steel to field sharpen. A choice steel to use for an everyday carry product.

4116: A fine grained stainless steel. The balance of Carbon and Chromium content give it a high degree of corrosion resistance and also impressive physical characteristics of strength and edge holding. Edge retention in actual cutting tests exceeded blades made of 420 and 440 series of stainless steels. Other alloying elements contribute to grain refinement which increase blade strength and edge toughness and also allow for a finer, sharper edge.

420J2: A good quality stainless steel commonly used in knife blades as well as for impact cutting tools such as axes, hatchets and machetes. Known as a hard, strong steel, this steel has decent edge holding capabilities and is easy to resharpen, stick-ing a good balance of the most desirable traits for knife steel.

2Cr13: A good quality stainless steel commonly used in knife blades as well as for impact cutting tools such as axes, hatchets and machetes. Known as a hard, strong steel, this steel has decent edge holding capabilities and is easy to resharpen.

3Cr13: A good quality stainless steel commonly used in knife blades as well as for impact cutting tools such as axes, hatchets, and machetes. Known as a hard, strong steel, this steel has decent edge holding capabilities and is easy to resharpen, sticking a good balance of the most desirable traits for knife steel.

7Cr17MoV: A good quality stainless steel that has a high tensile strength. This steel has excellent corrosion resistance and can be honed to a razor-sharp edge.

8Cr13MoV: A high quality stainless steel similar in properties to AUS-8. This steel exhibits extreme toughness and excellent edge retaining capabilities.

9Cr14MoV: A high-quality stainless steel. This steel has good corrosion resistance and excellent edge retaining capabilities.

9Cr18MoV: A higher-end stainless steel commonly used in precision surgical instruments. This steel has good corrosion resistance and excellent edge retaining capabilities.

AUS-8: A very high-quality stainless steel known for extreme toughness and excellent edge retaining capabilities. This steel has great corrosion resistance and is easy to sharpen.

D2: An air-hardened tool steel. Sometimes called a “semi-stainless” steel because it does contain 12% Chromium. This steel offers exceptional edge retention as well as decent corrosion resistance. Somewhat difficult to sharpen, this steel can be finished to a high polish shine.

SK-5: The Japanese equivalent of American 1080 steel, a high carbon steel with Carbon between 0.75%-0.85% and 0.60%-0.90% Manganese. This grade of steel has an ideal balance of very good blade toughness with superior edge holding ability and is used in a variety of hand tools and cutting products.

S30V: This steel contains Carbon along with high amounts of Chromium, Molybdenum and Vanadium. Double tempered for hardness and edge retention this steel has excellent corrosion resistance, but is somewhat difficult to sharpen.

Ceramic: A ceramic is an inorganic, non-metallic solid prepared by the action of heat and subsequent cooling. When used in the application of a knife blade, the ceramic material will stay sharp for much longer than that of a steel knife. The only drawback is the ceramic material is more brittle than steel and can snap from a hard impact.

Rockwell Test (HRC): A measurement of steel hardness based on the depth of penetration of a small diamond cone pressed into the steel under a constant load.

Tensile Strength: Indicated by the force at which a material breaks due to stretching. Provided by the elements Chromium (Cr) and Manganese (Mn).

Toughness: The ability of a material to resist shock or impact. Provided by the element Chromium (Cr).

1070: This is a plain carbon steel which means it has a low resistance to corrosion and low to medium edge retention. The benefit of this steel is that it is very easy to sharpen and will take an extremely sharp edge.

1095: This is a plain carbon steel which means it has a low resistance to corrosion and low to medium edge retention. The benefit of this steel is that it is very easy to sharpen and will take an extremely sharp edge.

4034: A good quality grade of stainless steel. This steel is known for its ability to be honed to a razor sharp edge. While this steel has medium edge retention it is a very easy steel to field sharpen. A choice steel to use for an everyday carry product.

4116: A fine grained stainless steel. The balance of Carbon and Chromium content give it a high degree of corrosion resistance and also impressive physical characteristics of strength and edge holding. Edge retention in actual cutting tests exceeded blades made of 420 and 440 series of stainless steels. Other alloying elements contribute to grain refinement which increase blade strength and edge toughness and also allow for a finer, sharper edge.

420J2: A good quality stainless steel commonly used in knife blades as well as for impact cutting tools such as axes, hatchets and machetes. Known as a hard, strong steel, this steel has decent edge holding capabilities and is easy to resharpen, stick-ing a good balance of the most desirable traits for knife steel.

2Cr13: A good quality stainless steel commonly used in knife blades as well as for impact cutting tools such as axes, hatchets and machetes. Known as a hard, strong steel, this steel has decent edge holding capabilities and is easy to resharpen.

3Cr13: A good quality stainless steel commonly used in knife blades as well as for impact cutting tools such as axes, hatchets, and machetes. Known as a hard, strong steel, this steel has decent edge holding capabilities and is easy to resharpen, sticking a good balance of the most desirable traits for knife steel.

7Cr17MoV: A good quality stainless steel that has a high tensile strength. This steel has excellent corrosion resistance and can be honed to a razor-sharp edge.

8Cr13MoV: A high quality stainless steel similar in properties to AUS-8. This steel exhibits extreme toughness and excellent edge retaining capabilities.

9Cr14MoV: A high-quality stainless steel. This steel has good corrosion resistance and excellent edge retaining capabilities.

9Cr18MoV: A higher-end stainless steel commonly used in precision surgical instruments. This steel has good corrosion resistance and excellent edge retaining capabilities.

AUS-8: A very high-quality stainless steel known for extreme toughness and excellent edge retaining capabilities. This steel has great corrosion resistance and is easy to sharpen.

D2: An air-hardened tool steel. Sometimes called a “semi-stainless” steel because it does contain 12% Chromium. This steel offers exceptional edge retention as well as decent corrosion resistance. Somewhat difficult to sharpen, this steel can be finished to a high polish shine.

SK-5: The Japanese equivalent of American 1080 steel, a high carbon steel with Carbon between 0.75%-0.85% and 0.60%-0.90% Manganese. This grade of steel has an ideal balance of very good blade toughness with superior edge holding ability and is used in a variety of hand tools and cutting products.

S30V: This steel contains Carbon along with high amounts of Chromium, Molybdenum and Vanadium. Double tempered for hardness and edge retention this steel has excellent corrosion resistance, but is somewhat difficult to sharpen.

Ceramic: A ceramic is an inorganic, non-metallic solid prepared by the action of heat and subsequent cooling. When used in the application of a knife blade, the ceramic material will stay sharp for much longer than that of a steel knife. The only drawback is the ceramic material is more brittle than steel and can snap from a hard impact.

Handle & Sheath Materials

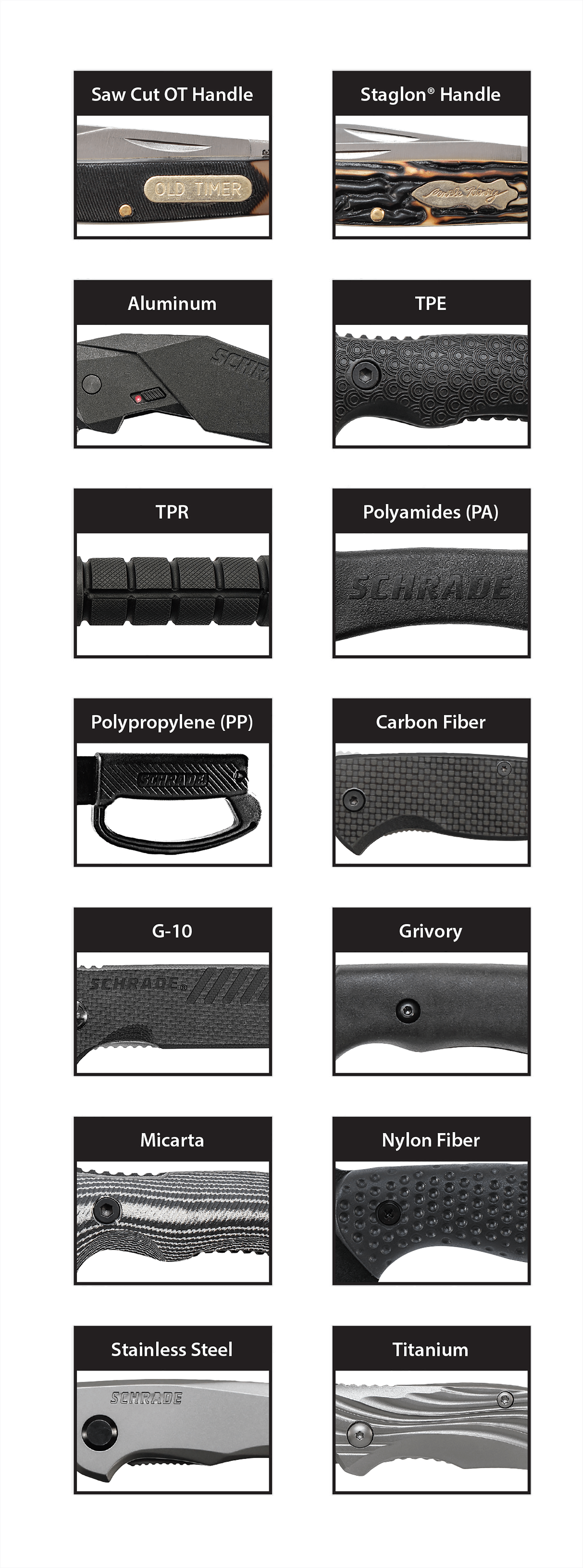

Saw Cut OT Handle Scales: This lightweight and durable polymer was engineered for its excellent longterm wear characteristics.Staglon® Handle Scales: This lightweight and durable polymer was engineered for its excellent longterm wear characteristics. Cosmetically designed to mimic Stag Horn.

Aluminum: Relatively soft, durable, lightweight, corrosion resistant, non-metallic metal. Aluminum has about one-third the density and stiffness of steel and is easily machined, cast, drawn and extruded.

TPE: This black thermoplastic elastomer is basically a softer version of TPR and offers a superb flexibility and memory elasticity even under harsh conditions. Most often molded onto a harder sub structure, TPE material offers excellent grip and comfort.

TPR: This thermoplastic rubber is best described as a material which has both the characteristics of rubber as well as plastic. TPR rubber is usually light in weight, has good tear strength, flexible in low temperature, weather-resistant, reusable and recyclable and it performs like vulcanized rubber.

PA: A plastic material Polyamides (PA) are semi-crystalline polymers. Polyamides have very good mechanical properties, are particularly tough and have excellent sliding and wear characteristics. Properties vary from the hard and tough PA 66 to the soft and flexible PA 12. Depending on the type, Polyamides absorb different amounts of moisture which also affect the mechanical characteristics.

PP: Polypropylene (PP) is a thermoplastic polymer used in a wide variety of applications. Commonly used in manufacturing processes such as injection molding.

Carbon Fiber: This material is a woven composite of graphite fibers fused together with an epoxy resin. The result is an ultra lightweight handle with an extreme tensile strength. Most often seen with a visible weave-like pattern which can be varied, as can the color of the epoxy used.

G-10: An epoxy filled woven “E” glass composite, reinforced with glass fibers for strength. Originally designed for circuit boards, G-10 offers the knife industry a handle which is impervious to most elements such as oils, water and acids. It can be produced in many colors and finished in a variety of ways, offering different amounts of texture matched to different end users.

Grivory: Polyphthalamide is a thermoplastic synthetic resin that can be used to replace metals in high temperature applications. This material is suitable for other applications such as handle materials in knives and other cutting tools. Typical characteristics are high heat resistance, high chemical resistance, abrasion/corrosion resistance, high tensile strength, high dimensional stability and direct bonding to many elastomers to give plastic-rubber composites.

Leather Sheaths: Our leather sheaths are made of 100% vegetable tanned top grain genuine cowhide. No finished split leather, bonded or imitation leather, nor any chrome tanned leather that can cause corrosion to the knife blades. The leather is “roller coated” for durability with a rich top coat finish. The tough, durable “roller coated” finish provides for protection from the outdoor elements, is more scratch resistant and has shown proven long-lasting wear. The sheaths are stitched with heavy-duty nylon thread in order to provide high tensile strength, durability and longterm wear. The 24 and 20 line durable and baby durable all metal snap fasteners are nickel-plated to prevent rust and corrosion. No plastic snaps are used. Many of the styles receive nickel-plated metal rivets in strategic locations to provide added strength, durability and safety.

Micarta: Technically described as “fabric reinforced phenolic laminate”, micarta is created by pouring a resin into a flat pan, then laying down a strip of linen or paper fabric, which then is saturated with the resin. This process is repeated until the desired thickness is achieved. Micarta can be in many different colors, is lightweight and can be finished in many ways.

Nylon Fiber: A synthetic thermoplastic polymer. Engineering grade nylon fiber is processed by extrusion, casting and injection molding and is available in glass-filled variants which increases structural, impact strength and rigidity.

Stainless Steel: A steel alloy with a minimum of 10.5% Chromium. Stainless steel does not readily corrode, rust or stain with water as ordinary steel does, it is not stain proof but rather stains less.

Titanium: A chemical element with the symbol Ti. It is a lustrous transition metal with a silver color, low density and high strength. Two of the most useful properties of the metal are corrosion resistance and the highest strength-to-weight ratio of any metal.

General Terms

Annodizing: An electro-chemical coating altering appearance and improving texture.Black Oxide: A coating used mostly on military knives to avoid reflection.

Black or Grey Ti: A thin black or grey coating of titanium carbonitride, provides corrosion resistance.

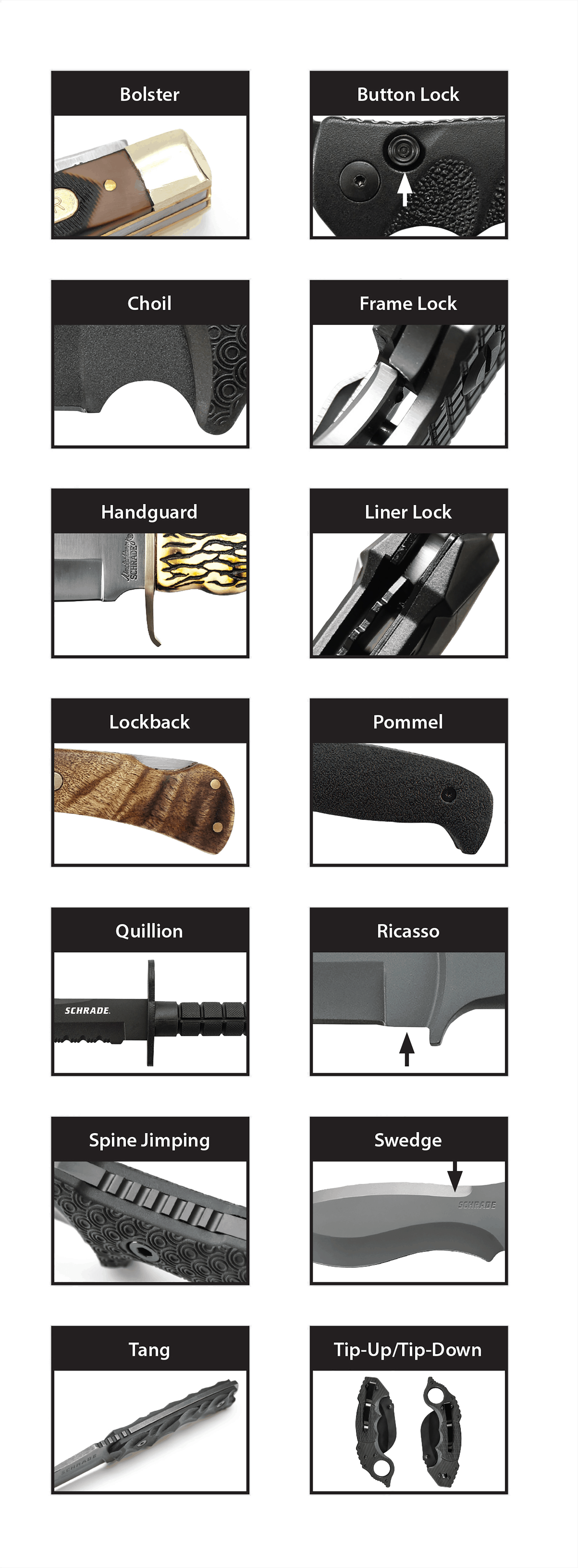

Bolster: A piece of metal, generally nickel-silver or stainless steel, that is located at one or both ends of a folding knife handle.

Button Lock: Found mainly on automatic knives, this type of lock uses a small push-button to open and release the blade.

Choil: A choil is a dip or cut out separating the cutting edge from the ricasso. It is also used to describe a cut out, molded or formed area where the handle and blade meet which positions/guards the index finger while gripping the opened knife.

Detent: A minute divot or dimple machined into the blade tang. A ball bearing drops into the detent hole when the knife is in the closed position, helping to hold the knife blade closed inside the handle.

Ergonomics: The applied science of equipment design intended to maximize productivity by reducing operator fatigue, safety and discomfort. Knives which are designed to be comfortable and less fatiguing when used are labeled “ergonomic”.

Finger Choil: A purposeful and specific area/curve cut-out between the blade and handle. It creates a grip position point closer to the cutting edge for better control while cutting.

Frame Lock: Also known as the integral lock or monolock, this locking mechanism works in a manner similar to the liner lock but uses a partial cut-out of the actual knife handle, rather than a separate liner inside the handle to hold the blade in place. To close you simply move the frame out of the way and rotate the blade into the closed position.

Handguard: Protrusion/expansion on the knife’s handle proximal to the blade keeping the hand safely positioned on the handle inhibiting sliding forward.

Lanyard Hole: A small hole in a knife’s handle for threading through a cord/string as a backup attachment when using the knife around water or where it may be dropped and lost.

Liner Lock: The liner lock’s locking side liner is split from the top toward the bottom, similar to an automotive leaf spring (also called a lock bar) that when the blade is fully open will butt up against the tang of the blade to prevent the blade from closing. To release the lock, the user presses the lock bar back toward the handle side, at which time the blade is free to close. In the closed position the lock bar (leaf spring) rests alongside the handle and the blade.

Lockback: Also known as a spine lock, the lockback includes a pivoted latch affixed to a spring, and can be disengaged only by pressing the latch down to release the blade.

M.O.L.L.E.: Modular Lightweight Load-Carrying Equipment is the current system of loadbearing equipment based in the Pouch Attachment Ladder System (PALS) used by military and law enforcement. It consists of a grid of nylon webbing allowing the modular attachment of pouches and other equipment to achieve customized and mission-specific configurations.

Pommel: The knob or expansion found on the butt-end of a knife handle.

Quillion: A handguard protruding from both sides of the handle (where handle and blade meet) stopping the hand from slipping up onto the blade.

Ricasso: Unsharpened and thicker portion of the blade, just before the handle. Allows users to choke up on the blade for better control.

Scale: A knife handle made of scales or slabs of material that are riveted, screwed or bonded together.

Skeletonized Liners: Internal steel handle liners that are hollowed out (skeletonized). In removing sections of the steel, bulk and weight are reduced while allowing the liner to maintain its strength and rigidity.

Slip Joint: Non-Locking Blade: blade having a spring acting against it, which provides some resistance to its opening and closing as it pivots within the handle.

Spine Jimping: Small serrations, notching or texturing located on the spine of a blade where the hand or finger grips. Jimping creates tactile resistance, adds purchase, traction and slip resistance.

Swedge: Blade grind where a portion of the blade’s spine is removed to reduce weight, add style to a blade or both.

Tang: The portion of the blade where it connects to the handle.

Tip-Up/Tip-Down: Refers to which direction the folded knife is positioned by its pocket clip. When closed and clipped in a pocket, whichever direction (up or down) the blade’s tip sits defines if it is termed tip-up or tip-down.